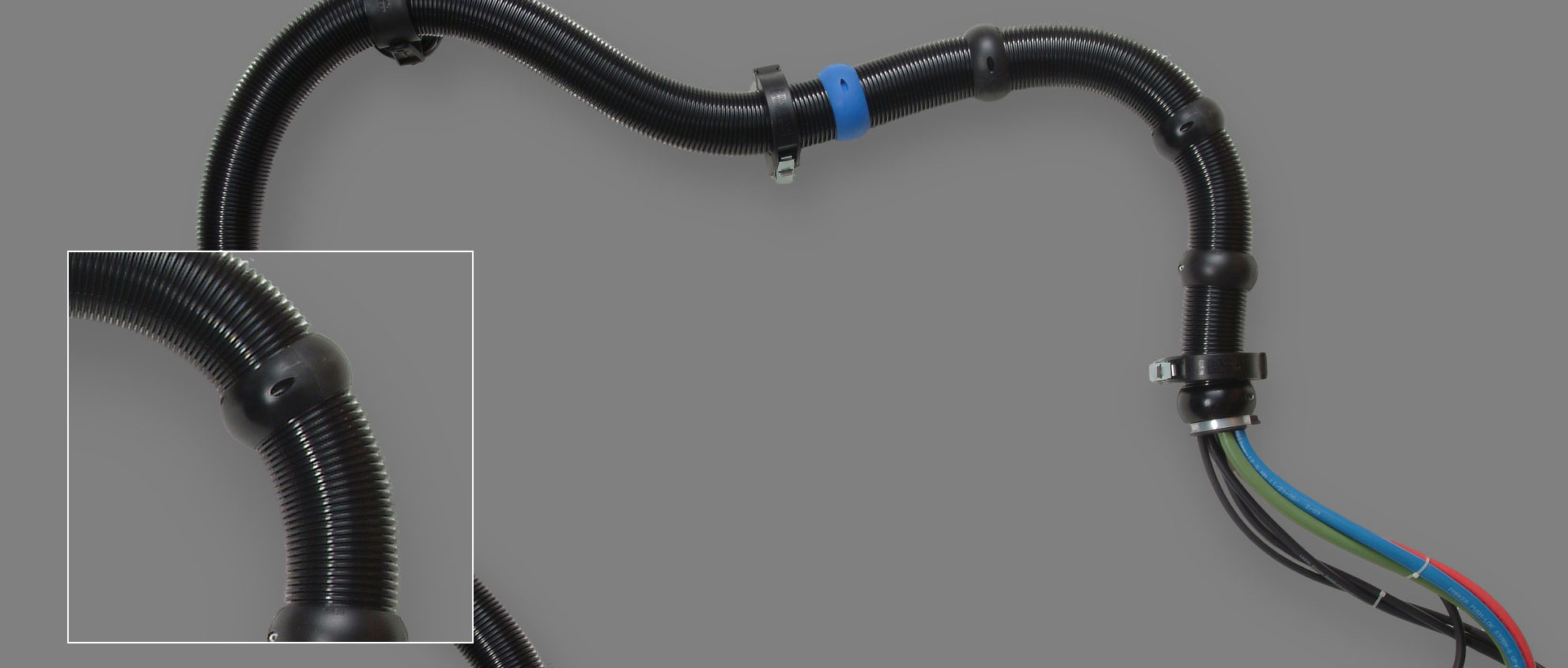

All conduits are not created equal. REIKU’s patented conduit profile allows for a tighter bending radius without reducing the conduit’s inside diameter. REIKU recommends a maximum 75% conduit fill capacity in order to prevent the chafing of cables and hoses.

REIKU conduit part numbers contain the actual Inside Diameter or I.D. of the conduit in millimeters.

PARA Series

PARA series conduits are derived from REIKU’s proprietary blend of highly flexible Nylon 12 raw material. PARAB is extremely durable and has been tested to withstand over 15 million continuous minimum to maximum bend radius cycles which is why it is used in a very high percentage of Robotics applications. The “tight” molecular structure of nylon 12 combats the absorption of fluids and provides great solvent and chemical resistance properties also. PWIS Certified to be free from contaminants such as grease, mineral oils and silicons making it ideal for use in Robotic paint applications /paint booths.

PARR Series

PARF Series

BIORR Series

PURR series

PURV series

PURV series SUPER Hi FLEX Robotics polyurethane based Robotics conduit. Superior flexibility, but softer conduit tested to withstand between 5 and 7 million continuous minimum to maximum bend radius cycles . The PURV series of Robotics conduit has a heavier /thicker wall structure offering more mechanical protection than the PURR but is still very soft . Also used in applications where extreme bend radius expectation is required and also softer than the stiffer Nylon conduits that might scratch finished surfaces. Lower mechanical protection and potential for “ripping” due to the very soft polyurethane raw material.